Ever wonder what separates a kitchen cutting board from a dangerous one? The answer lies in something most people never think about: the finish.

Not all wood finishes are safe for food contact, which is why choosing a food-safe option protects both your kitchen items and your family’s health.

But here’s the catch: not every product labeled “natural” is truly safe.

Some finishes claim to be food-friendly when they’re actually hiding harmful ingredients. Want to know which finishes you can really trust with your next meal?

What Does Food Safe Really Mean?

Understanding what qualifies a food-safe wood finish starts with knowing how these products interact with food surfaces.

A finish earns this designation when it contains no toxic ingredients that could transfer into food after proper curing.

Look for products labeled “food safe,” “FDA compliant,” or meeting NSF standards. These certifications guarantee the finish has been tested and approved for direct food contact.

Regular furniture finishes pose serious risks because they contain chemicals that can migrate into food, especially when heated or combined with acidic ingredients.

Standard varnishes, polyurethanes, and furniture stains simply weren’t formulated with food safety in mind, making them unsuitable for cutting boards and serving pieces.

What to Look For in a Food Safe Wood Sealer?

Selecting the right food-safe wood sealer requires evaluating several key performance factors. The best products balance safety with durability while maintaining the natural feel of wood that makes cutting boards so desirable for kitchen use.

- The sealer should contain zero harmful chemicals, heavy metals, or volatile organic compounds that could contaminate food during meal preparation.

- Quality sealers create barriers that prevent moisture penetration, stop stains from setting into the grain, and keep foods like garlic and onions from leaving lingering smells.

- Look for products that go on smoothly without specialized equipment and can be reapplied easily when the surface needs refreshing after months of use.

- The best food-safe wood finish creates a smooth, gentle surface that won’t dull knife edges quickly while still providing adequate protection for the wood underneath.

Types of Food-Safe Wood Finishes

Choosing the right food-safe wood finish depends on understanding how different products protect wood and perform under daily kitchen use.

Each finish type offers unique advantages, from deep penetration to surface protection, making some better suited for cutting boards while others work well for decorative wooden bowls and serving pieces.

1. Mineral Oil

Food-grade mineral oil remains the most popular food-safe wood finish for treating cutting boards because it’s affordable, safe, and easy to find.

This petroleum-derived oil penetrates wood fibers without ever drying or hardening, keeping the wood supple and preventing cracks.

- Best use: Ideal for cutting boards, butcher blocks, and any wooden kitchen items that come into frequent knife contact or undergo heavy chopping.

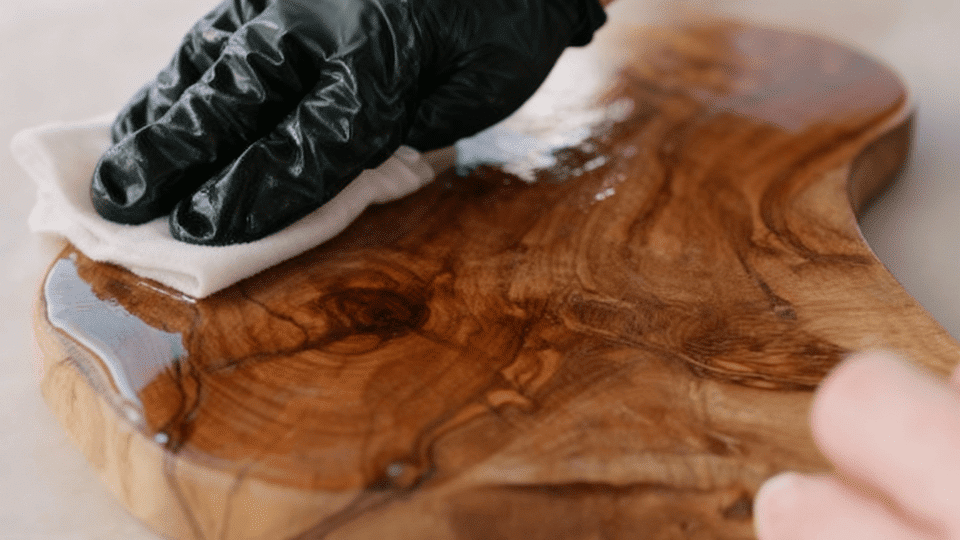

- How to use: Apply a generous coat with a clean cloth, let it soak in for several hours or overnight, then wipe away excess oil before using the board.

- Key considerations: Mineral oil never fully cures, so it requires reapplication every few weeks or whenever the wood appears dry and loses its slight sheen.

2. Natural Drying Oils

Pure tung oil, raw linseed oil, and walnut oil cure by oxidation, forming a harder, more protective layer than mineral oil. These food-safe wood sealers enhance the wood’s natural grain and provide better moisture resistance once fully cured.

- Best use: Perfect for wooden bowls, serving platters, and cutting boards that need more durable protection than mineral oil provides while maintaining a natural appearance.

- How to use: Apply thin coats with a lint-free cloth, allow each coat to dry completely (24-48 hours), then sand lightly between coats for best results.

- Key considerations: Nut-based oils like walnut oil can trigger severe allergic reactions in sensitive individuals, making them unsafe for items used by multiple people or guests.

3. Wax and Oil Blends

Beeswax and carnauba wax, combined with mineral oil or natural oils, create board creams that offer superior water resistance.

The wax component sits on the wood surface, creating a protective barrier that repels liquids better than oil alone as a food-safe wood sealer.

- Best use: Excellent for cutting boards and butcher blocks that need water protection, as well as wooden utensils and serving pieces that come into contact with moist foods regularly.

- How to use: Warm the blend slightly if solid, rub it into the wood with a cloth in circular motions, let it sit for 20-30 minutes, then buff to a soft luster.

- Key considerations: Wax blends provide better protection than plain oils but still require periodic reapplication, typically every month or two, depending on usage frequency.

4. Hardening Film Finishes

Some hard oils and water-based film finishes become food contact safe after complete curing, creating a durable surface layer. These food-safe wood finishes offer better protection against moisture and staining than penetrating oils.

- Best use: Suitable for decorative wooden bowls, charcuterie boards, and serving trays that won’t come into direct knife contact or undergo aggressive scrubbing during cleaning.

- How to use: Apply multiple thin coats according to manufacturer instructions, allowing full cure time between coats, and wait the recommended period before food contact.

- Key considerations: Film finishes create hard surfaces that can chip or scratch when knives are used, making them poorly suited for actual cutting boards despite their food-safe designation.

Choosing the Best Food Safe Wood Finish

Selecting the ideal food-safe wood finish involves matching product features to specific needs. Different cutting boards vary from casual prep to heavy butchering, each requiring specific qualities.

| FACTOR | MINERAL OIL | NATURAL OILS | WAX BLENDS | FILM FINISHES |

|---|---|---|---|---|

| Protection Level | Basic moisture resistance | Superior once cured | Excellent water barrier | Strongest but can chip |

| Maintenance | Every 2-4 weeks | Every 2-3 months | Monthly | Rarely, but hard to repair |

| Appearance | Natural look, smooth feel | Deepens color, increases grain | Subtle sheen, satin finish | Can alter significantly |

| Safety Check | Look for USP grade purity | Verify food grade, check allergens | Confirm that all ingredients are food safe | Must state that food contact is safe after curing |

Tips for Getting the Best Results

Applying a food-safe wood finish correctly differs between adequate protection and exceptional performance. Proper technique ensures deep penetration, complete curing, and lasting protection for cutting boards and wooden kitchen items.

- Choose the right finish for the wood type: Softwoods such as pine and cedar absorb food-safe wood sealers faster and more than dense hardwoods like maple or walnut, requiring adjustments in application to avoid over-saturation or undercoverage.

- Apply multiple thin coats: Thin layers penetrate wood fibers more effectively than heavy applications, which tend to pool on the surface and create sticky residue that attracts dust and never fully absorbs into the grain for proper protection.

- Let the finish fully cure: Adequate drying time lets oils oxidize and waxes harden, turning them into stable, food-safe finishes that won’t transfer onto hands or food.

- Warm the finish slightly before applying: Gently heating mineral oil or wax blends reduces viscosity, allowing the food-safe wood sealer to flow into tight wood grain and penetrate deeper for more thorough protection and better moisture resistance.

- Always test on a small area: Applying the finish to an inconspicuous spot first reveals how the wood will darken, whether the grain will pop dramatically, and if the absorption rate matches expectations before committing to the entire surface.

Which One Should You Choose?

Your decision hinges on your board’s purpose and personal preferences. If simplicity and low cost appeal to you, mineral oil delivers reliable results.

Tung oil suits those seeking greater durability and beautiful grain enhancement. Wax-oil combinations strike a balance, pairing straightforward application with solid moisture defense.

Hardening finishes excel on display pieces or serving boards where knives won’t make contact. Whichever option you select, complete curing is non-negotiable before any food comes into contact with the surface.

Conclusion

Protecting your wooden kitchen items is simple once you know the basics. Whether you choose mineral oil, natural oils, or wax blends, each finish has its purpose.

Match the finish to your item’s purpose, follow the application steps, and keep up with regular maintenance to ensure lasting protection.

Ready to give your cutting board the protection it deserves? Grab some food-safe finish and get started today.