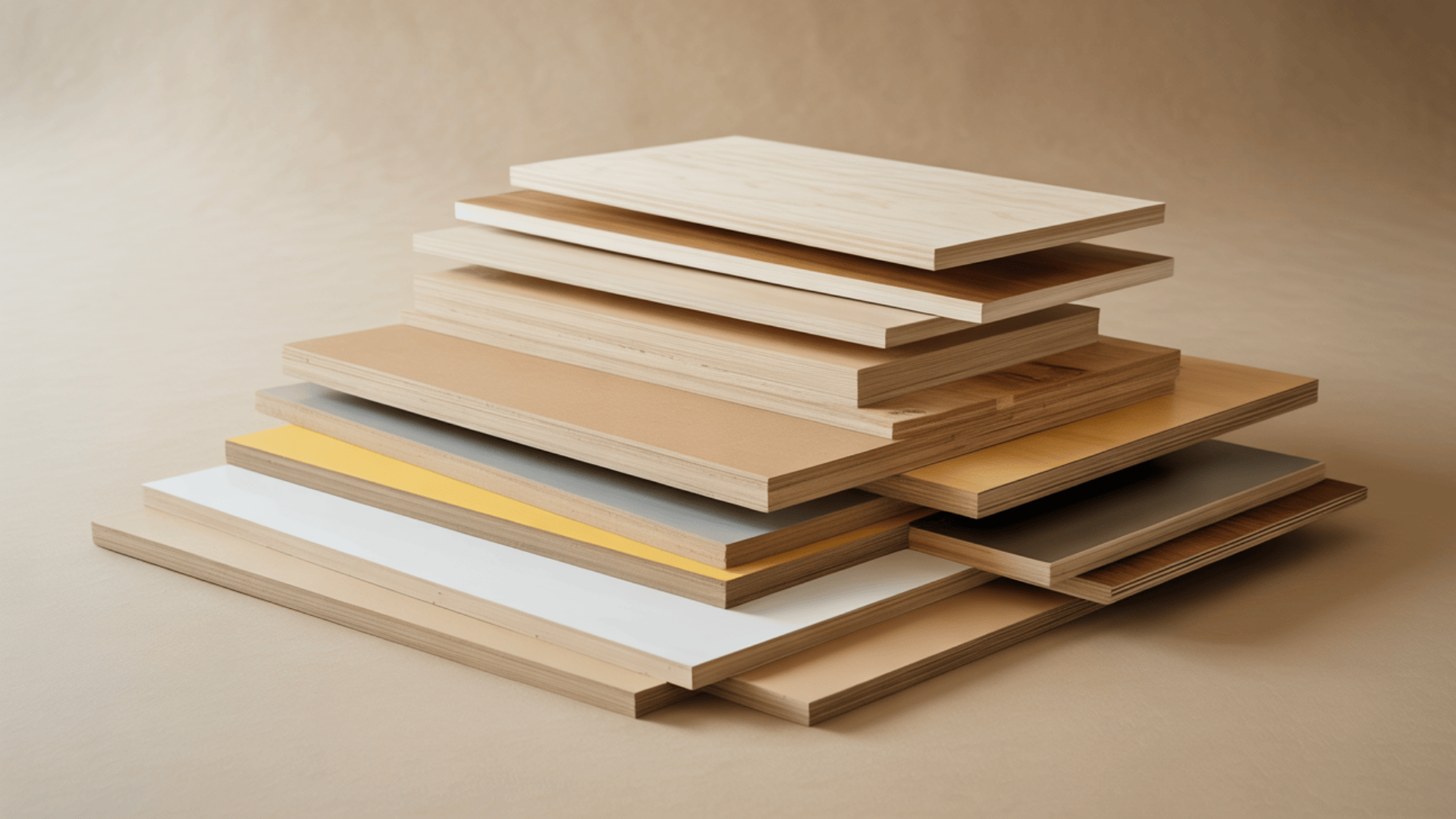

When I first walked into a hardware store looking for plywood, something caught my attention: plywood isn’t just plywood.

Different types of plywood suit specific jobs; some resist water, while others are suitable for indoor or outdoor use.

Understanding what sets each variety apart can save you time, money, and headaches on your next project. Let’s find what makes each type unique and which one fits your needs.

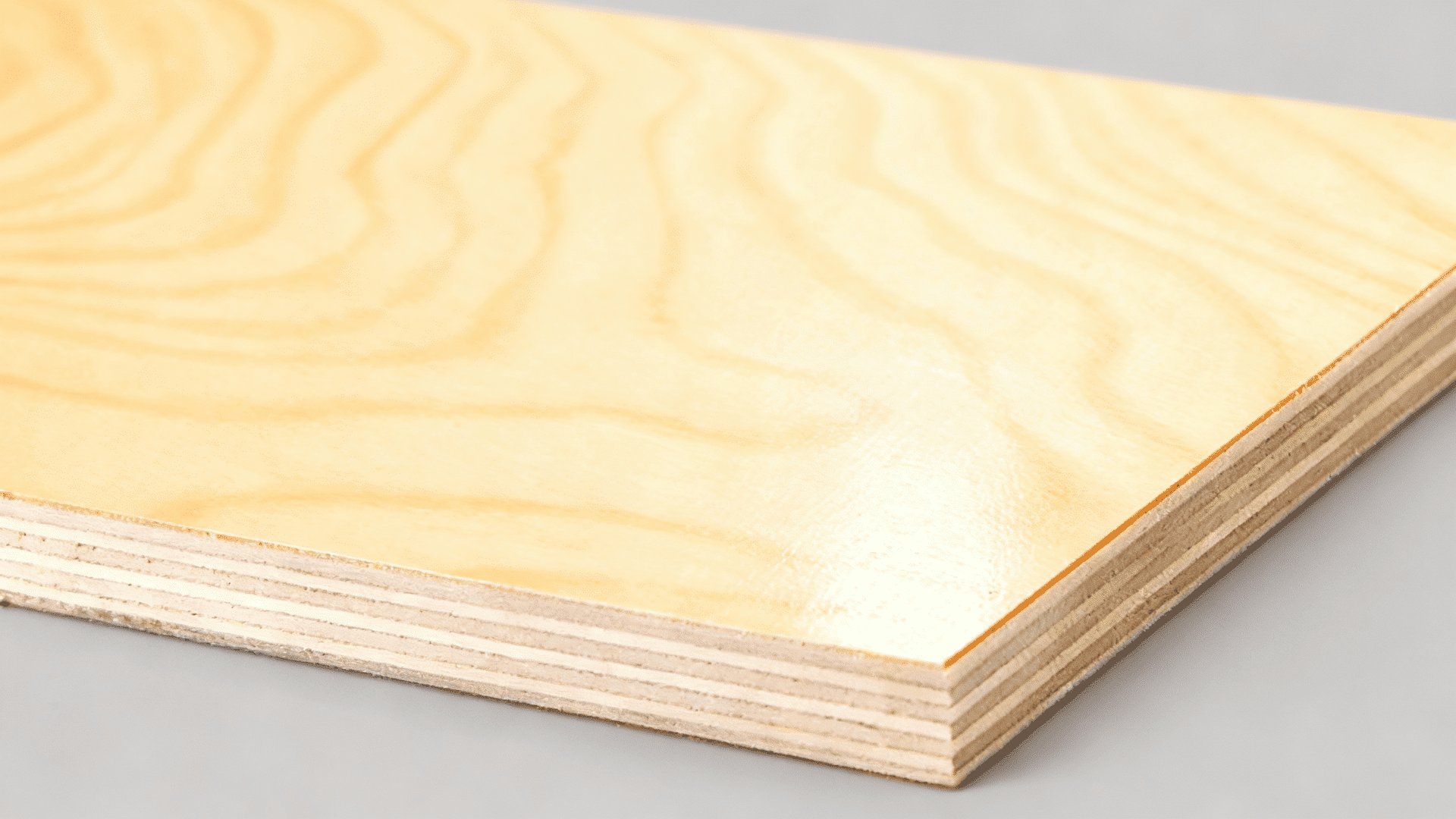

Decoding the Layers That Make Plywood

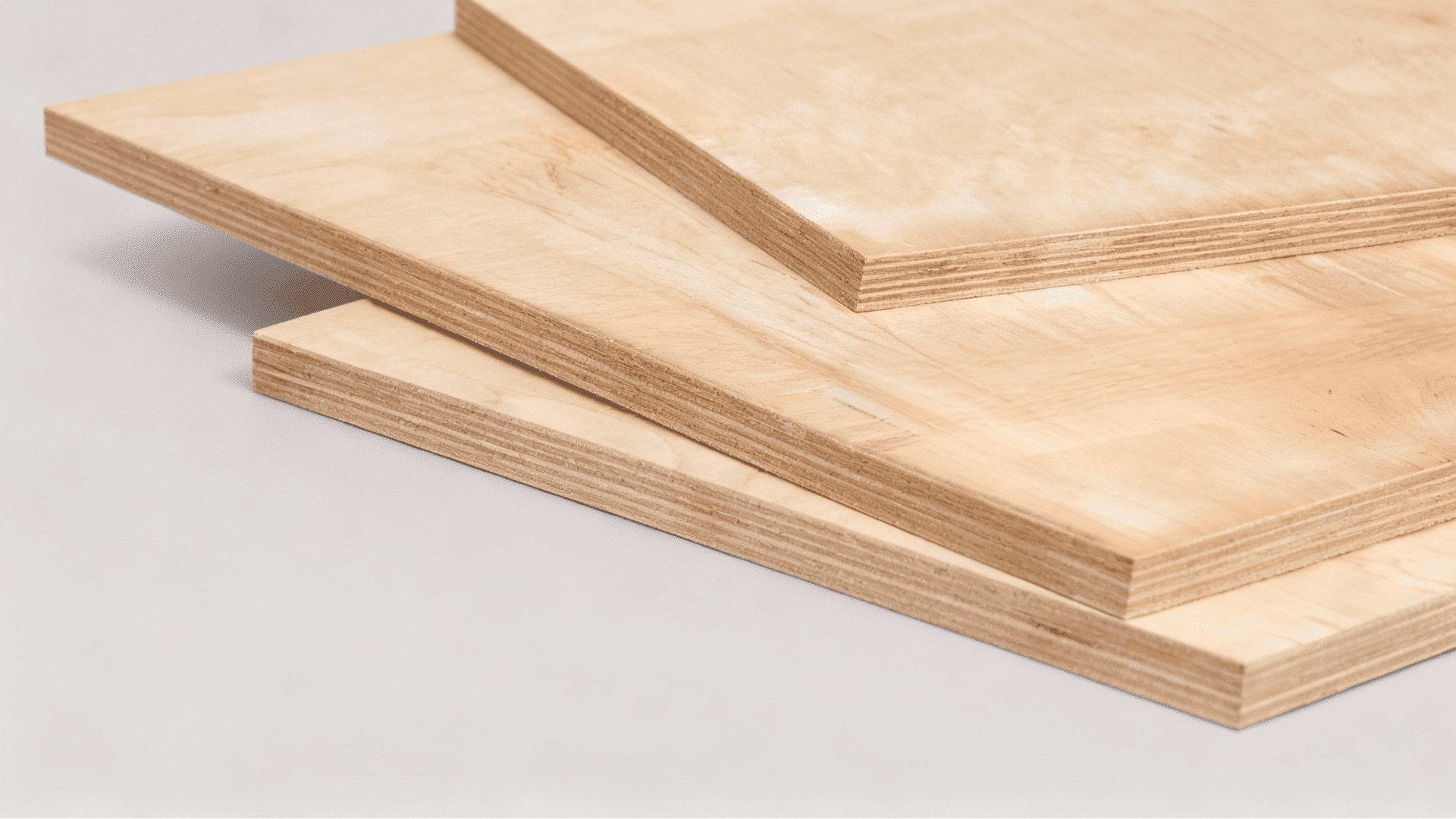

Plywood is an engineered wood material made by gluing together thin layers of wood veneer. Each layer, called a ply, is stacked with its grain running perpendicular to the next, creating exceptional strength and stability.

This cross-grain construction prevents warping and splitting, making plywood types more durable than solid wood. You’ll find it used in everything from structural framing to decorative furniture and even types of windows.

The number of plies determines thickness and strength, with options ranging from 3-ply to 13-ply sheets. Different types of plywood serve specific purposes based on their grade, core material, and moisture resistance.

Different Types of Plywood By Construction

Plywood construction methods determine how core layers are assembled in different types of plywood, directly affecting strength, flexibility, and cost, helping you pick the right material for your project.

1. Softwood Plywood

Softwood plywood prioritizes strength and affordability, making it the go-to choice for structural applications. You’ll find softwood plywood used in construction sites more than anywhere else because it handles heavy loads without breaking the bank.

- Made From: Pine, fir, cedar, spruce, redwood veneers

- Grades Available: A-A, A-B, A-C, B-C, C-D (exterior and interior grades)

- Common Uses: Roof sheathing, wall sheathing, subfloors, concrete formwork, crates

- Pros: Strong, affordable, lightweight, readily available, good for structural work

- Cons: Rough surface finish, visible grain patterns, requires sanding for a smooth finish

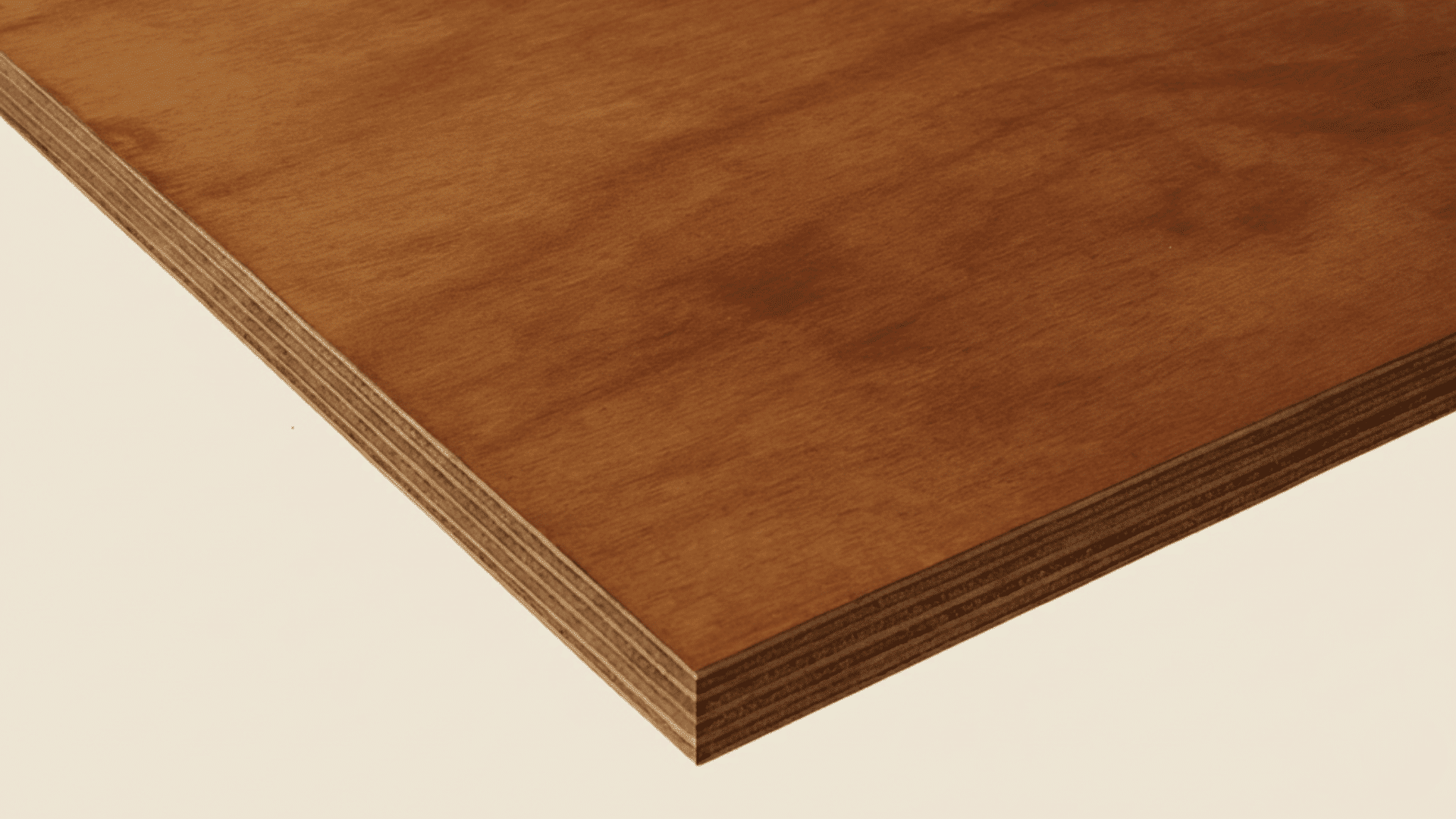

2. HardwoodPlywood

Hardwood plywood uses deciduous tree veneers for the face layers, creating beautiful grain patterns and smooth surfaces. It’s the preferred choice when aesthetics matter, such as in furniture-making, decorative wall panels, and window casings.

- Made From: Oak, maple, birch, cherry, walnut, mahogany, ash veneers

- Grades Available: A, B, C, D (face grade) and 1, 2, 3, 4 (back grade)

- Common Uses: Fine furniture, cabinets, decorative panels, musical instruments, interior trim

- Pros: Beautiful appearance, smooth finish, takes stain well, durable face veneers

- Cons: More expensive, less structural strength than softwood, requires careful handling

3. Structural Plywood

Structural plywood is engineered specifically for load-bearing applications and meets strict building codes. This construction uses thick veneers and high-grade adhesives that bond under pressure, creating exceptional strength and rigidity.

- Made From: Douglas fir, southern pine, or other approved structural wood species

- Grades Available: Structural I, Structural II, rated sheathing, marine grade

- Common Uses: Floor joists, roof trusses, wall bracing, I-beams, heavy-duty shelving

- Pros: Highest strength-to-weight ratio, meets building codes, excellent load capacity, moisture-resistant options

- Cons: Premium pricing, overkill for non-structural projects, limited decorative appeal

4. Veneer Core Plywood

Veneer core is the most common type, built entirely from thin wood layers glued together. Each ply alternates grain direction for balanced strength and stability.

This construction offers excellent screw-holding power and works well for both structural and decorative projects.

- Made From: Hardwood or softwood veneers (birch, oak, pine, fir)

- Grades Available: A, B, C, D (A being highest quality)

- Common Uses: Cabinets, furniture, wall paneling, roofing, subfloors

- Pros: Affordable, strong, lightweight, widely available

- Cons: Can show voids in lower grades, edges need finishing

5. Lumber Core Plywood

Lumber core features solid wood strips in the center, sandwiched between veneer layers. This construction creates exceptional strength and superior screw-holding ability compared to the veneer core.

It’s heavier but ideal when you need maximum durability and load-bearing capacity for demanding applications.

- Made From: Solid wood strips (poplar, basswood) with hardwood or softwood face veneers

- Grades Available: Premium, cabinet grade, utility grade

- Common Uses: Heavy-duty shelving, workbenches, table tops, butcher blocks

- Pros: Extremely strong, holds screws better, minimal warping, easy to machine

- Cons: More expensive, heavier than veneer core, limited availability

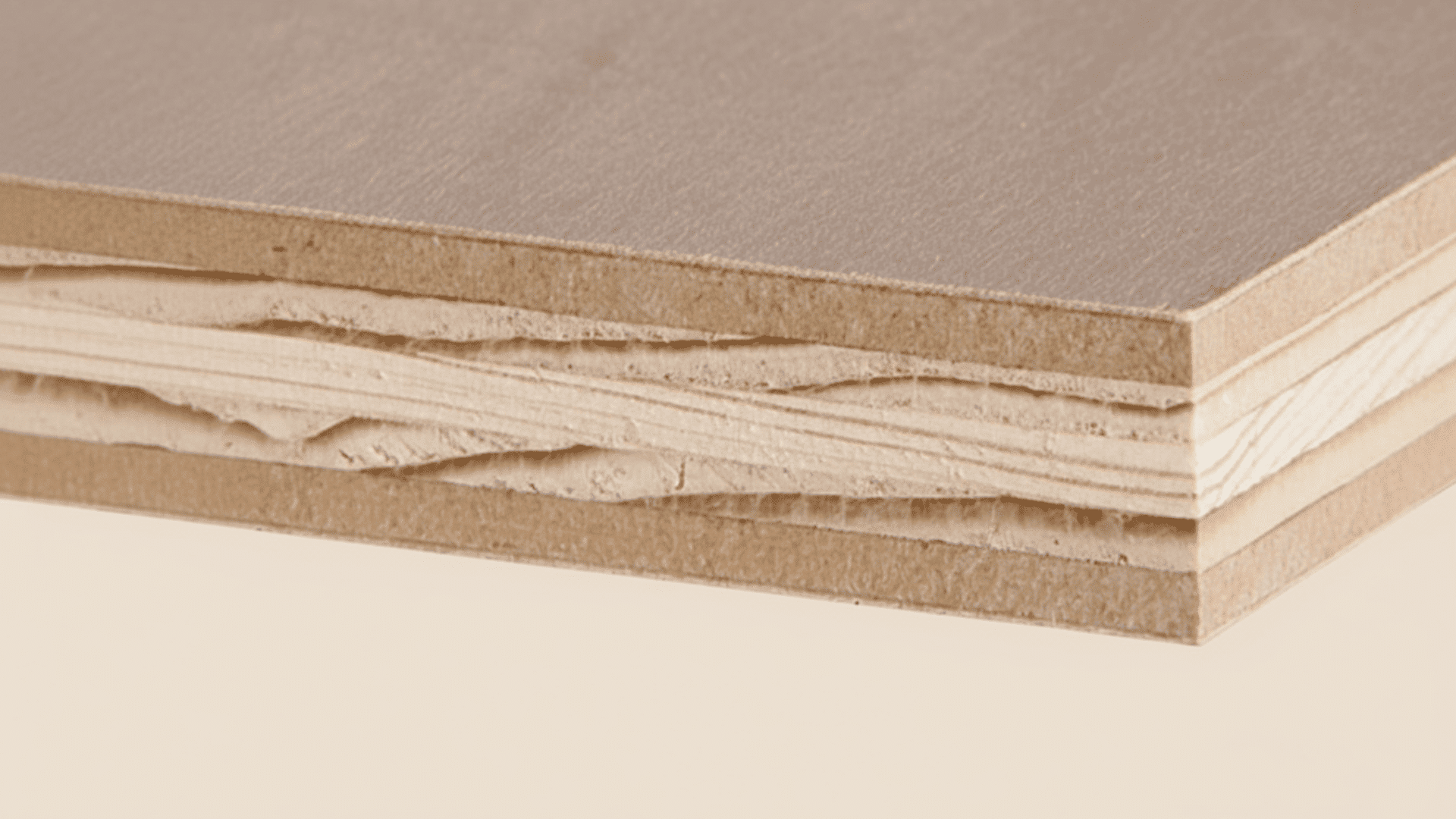

6. Particleboard Core Plywood

Particleboard core uses compressed wood particles as the center layer, covered with thin veneers on both faces. This budget-friendly option works well for indoor projects where moisture isn’t a concern.

- Made From: Compressed wood particles with decorative face veneers (oak, maple, cherry)

- Grades Available: Industrial grade, furniture grade, premium grade

- Common Uses: Kitchen cabinets, closet organizers, store fixtures, laminated furniture

- Pros: Cost-effective, smooth surface, consistent thickness, good for veneering

- Cons: Poor moisture resistance, lower strength, difficult to hold screws, heavy

7. MDF Core Plywood

MDF (Medium Density Fiberboard) core combines fine wood fibers with resin, then adds veneer faces. This creates an ultra-smooth surface that’s perfect for painting and detailed work.

- Made From: Fine wood fibers and resin with hardwood or decorative veneers

- Grades Available: Standard MDF, moisture-resistant MDF, fire-rated MDF

- Common Uses: Painted cabinets, decorative panels, speaker boxes,

- Pros: Very smooth finish, no grain show-through, excellent for painting, uniform density

- Cons: Heavy, poor moisture resistance (unless treated), doesn’t hold screws as well

Each construction type serves different purposes, so matching the right one to your project saves money and ensures lasting results. Consider your budget, the environment where it’ll be used, and the strength requirements before making your final choice.

Specialty Plywood Types for Specific Applications

Some projects demand more than standard plywood can offer. Specialty plywood types are engineered to handle extreme conditions like moisture, fire, or flexibility requirements.

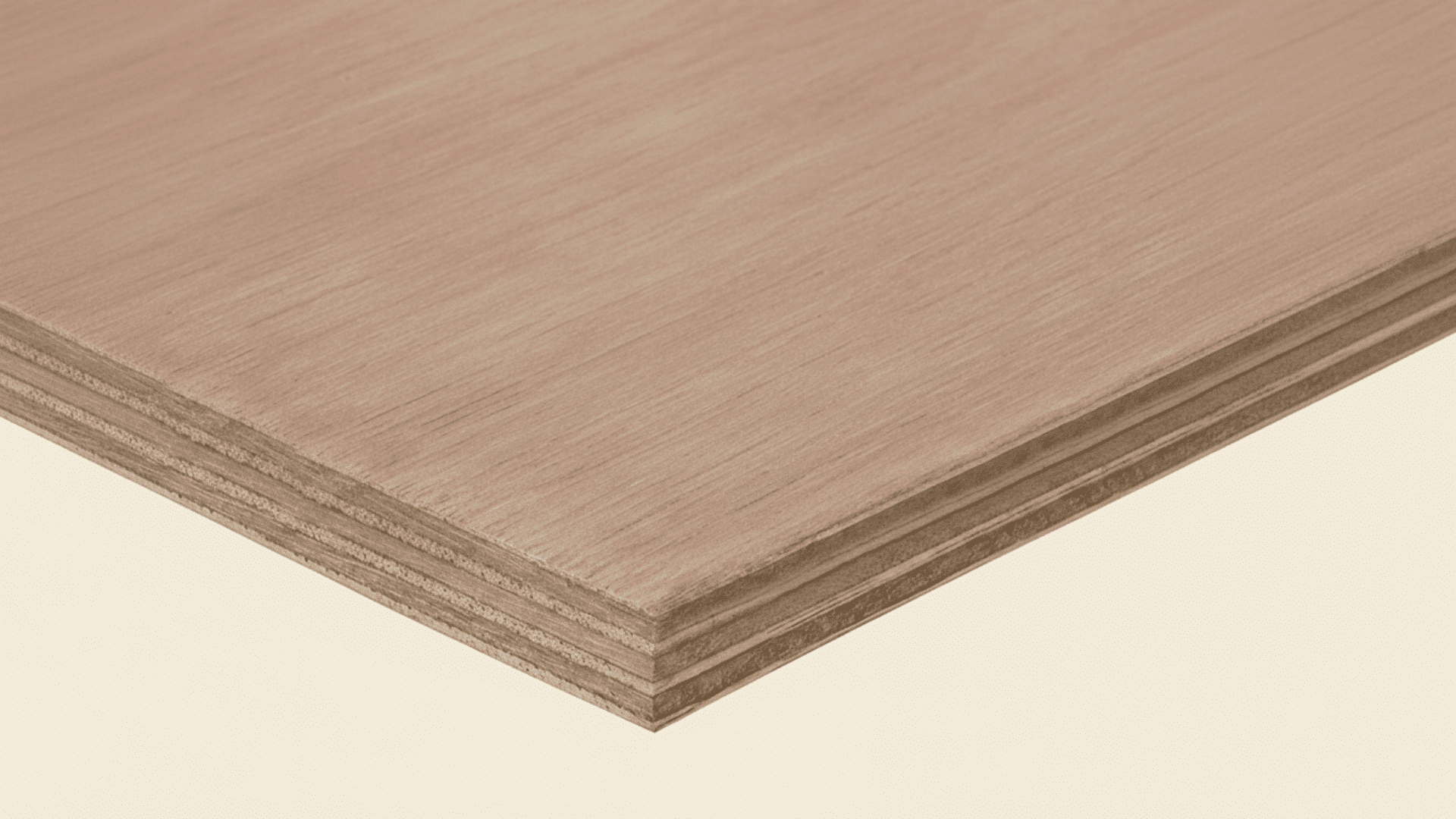

8. Marine Plywood

Marine plywood is built to survive constant water exposure without falling apart. It uses waterproof glue and high-quality veneers with no gaps or voids that could trap moisture.

- Made From: Douglas fir, western larch, or tropical hardwoods (okoume, meranti) with waterproof phenolic resin

- Grades Available: BS 1088 (British Standard), AS/NZS 2272 (Australian), A-A, A-B marine grades

- Common Uses: Boat building, docks, exterior furniture, bathroom cabinets, outdoor kitchens

- Pros: Excellent water resistance, void-free construction, extremely durable, long lifespan

- Cons: Expensive, heavier than standard plywood, limited availability, requires proper sealing

9. Fire-Retardant Plywood

Fire-retardant plywood is chemically treated to slow the spread of flames and reduce smoke production during fires. This specialty type meets strict building codes for commercial spaces, schools, and high-rise buildings.

- Made From: Softwood or hardwood veneers treated with fire-retardant chemicals (pressure-impregnated)

- Grades Available: Class A (flame spread 0-25), Class B (26-75), Class C (76-200)

- Common Uses: Commercial buildings, schools, hospitals, theaters, hotels, high-rise apartments

- Pros: Slows fire spread, meets building codes, reduces smoke, insurance benefits

- Cons: Very expensive, chemical treatment adds weight, can corrode metal fasteners, limited outdoor use

10. Flexible Plywood

Flexible plywood bends easily without breaking, making it perfect for curved surfaces and rounded designs. This specialty sheet uses thinner cross-grain veneers that allow controlled flexing in one direction.

- Made From: Thin hardwood veneers (usually 3-5 plies) with specific grain orientation for flexibility

- Grades Available: Long-grain flex (bends lengthwise), cross-grain flex (bends widthwise)

- Common Uses: Curved furniture, arches, columns, skateboard ramps, boat interiors, types of windows with curves

- Pros: Bends without breaking, saves construction time, smooth curves, lightweight

- Cons: Limited availability, more expensive, lower strength, requires a support structure

11. Aircraft Plywood

Aircraft plywood represents the highest quality standard, originally developed for airplane construction.

It uses premium hardwood veneers with absolutely no defects and superior adhesives for a maximum strength-to-weight ratio.

- Made From: Birch, mahogany, or spruce veneers with phenolic resin adhesive (void-free, defect-free)

- Grades Available: Aircraft grade (meets MIL-SPEC standards), premium birch grades

- Common Uses: Model aircraft, high-end furniture, musical instruments, racing boat components, precision work

- Pros: Highest quality available, extremely strong, lightweight, perfect surface, no voids

- Cons: Very expensive, overkill for most projects, limited suppliers, requires special ordering

12. Pressure-Treated Plywood

Pressure-treated plywood is infused with preservatives that protect against rot, insects, and fungal decay. The treatment process forces chemicals deep into the wood fibers under high pressure, creating long-lasting protection.

- Made From: Softwood plywood (pine, fir) pressure-treated with copper-based preservatives (ACQ, CA-B)

- Grades Available: Ground contact, above ground, marine applications (based on retention levels)

- Common Uses: Deck foundations, outdoor sheds, raised garden beds, exterior siding, crawl spaces

- Pros: Rot-resistant, insect-proof, long outdoor lifespan, ground-contact safe

- Cons: Contains chemicals, requires special fasteners, heavier, can’t be used indoors, needs weathering before painting

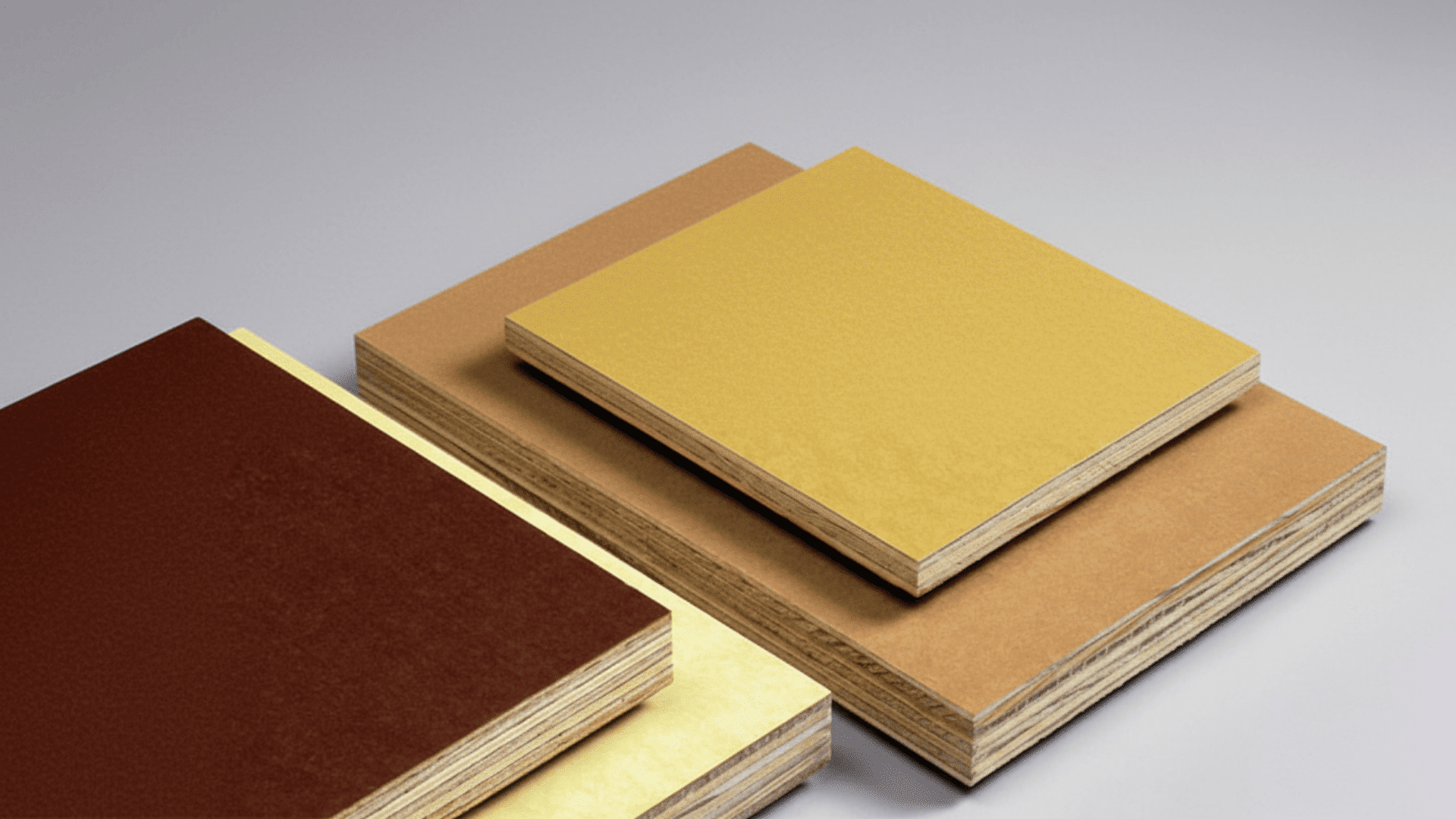

13. Overlaid Plywood (HDO/MDO)

Overlaid plywood features a resin-fiber surface bonded to standard plywood cores. HDO (High Density Overlay) and MDO (Medium Density Overlay) create ultra-smooth, weather-resistant surfaces that don’t need paint but accept it beautifully.

- Made From: Softwood plywood core with phenolic resin-impregnated fiber overlay

- Grades Available: HDO (high density), MDO (medium density), sign-grade MDO

- Common Uses: Concrete forms, exterior signs, cabinets, types of window trim, soffits, and agricultural buildings

- Pros: Smooth finish, weather-resistant, reusable for concrete forms, paint-ready surface

- Cons: More expensive, heavier, limited decorative options, overlay can chip at edges

These specialty plywood types solve specific problems that standard sheets can’t handle. Match your project’s unique demands with the right specialty material, and you’ll get professional results that last for years.

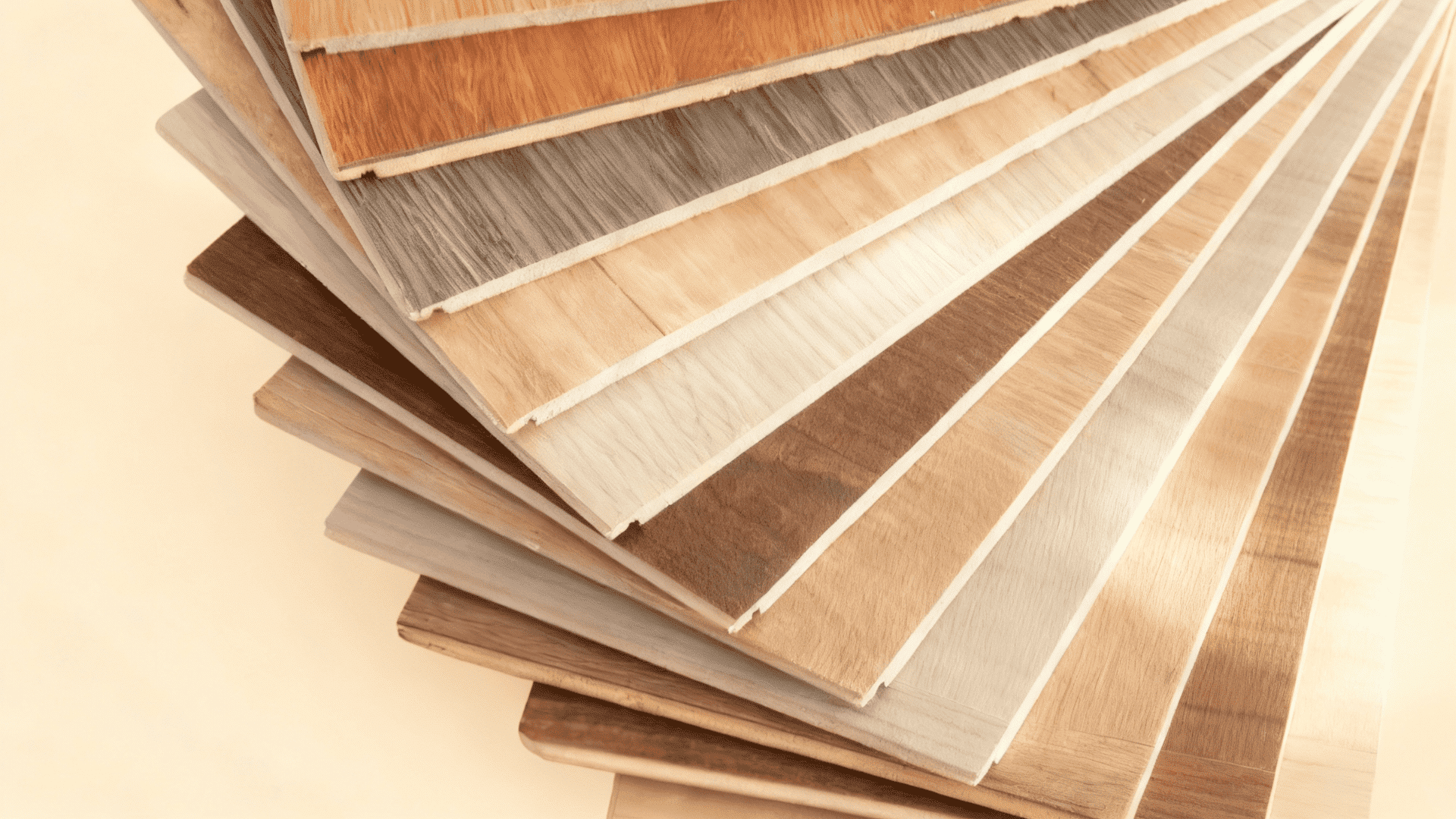

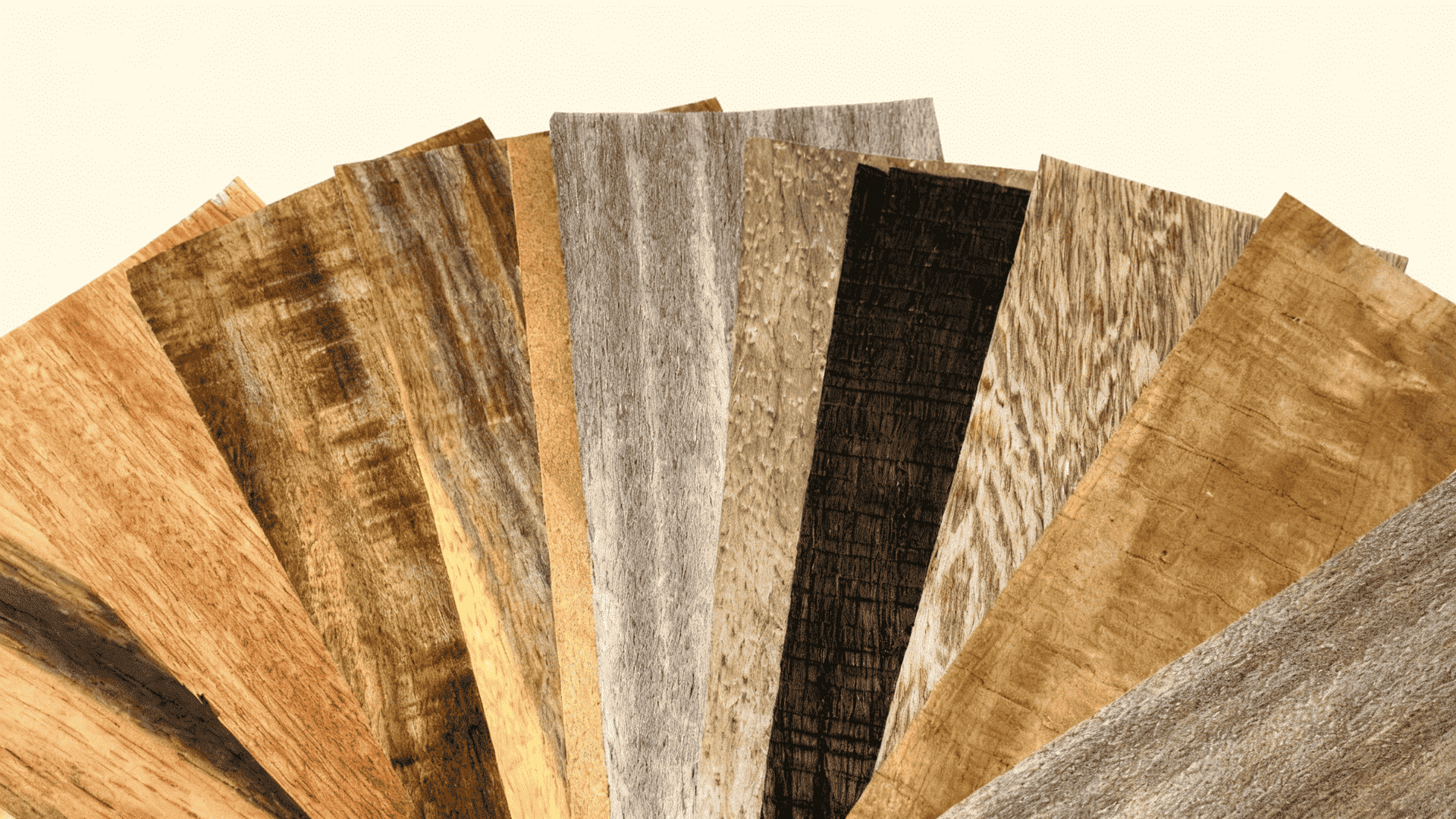

Decorative Plywood Options

When appearance matters as much as function, decorative plywood delivers stunning finishes at a fraction of the cost of solid wood.

These different types of plywood feature beautiful face veneers and special treatments that change ordinary surfaces into eye-catching focal points.

14. Bamboo Plywood

Bamboo plywood uses renewable bamboo strips instead of traditional wood veneers, creating eco-friendly sheets with distinctive linear patterns.

Different types of bamboo plywood bring natural warmth and modern appeal to spaces while supporting environmentally conscious building practices.

- Made From: Laminated bamboo strips with cross-grain construction, bonded with low-VOC adhesives

- Grades Available: Horizontal grain, vertical grain, strand-woven (highest density)

- Common Uses: Countertops, furniture, cabinets, flooring underlayment, decorative panels, windows blinds

- Pros: Eco-friendly, renewable resource, unique appearance, hard and durable, moisture resistant

- Cons: Expensive, limited availability, can darken over time, adhesives vary in quality

15. Calibrated Plywood

Calibrated plywood is precision-sanded to exact thickness specifications, eliminating the variations you’d find in standard sheets.

Furniture makers and woodworkers pay extra for calibrated sheets because they save hours of sanding and fitting time.

- Made From: Hardwood or softwood plywood precision-sanded to uniform thickness (typically birch, maple, oak)

- Grades Available: A-grade face, B-grade face, cabinet grade, furniture grade

- Common Uses: Cabinet boxes, drawer construction, furniture frames, jigs, templates, precision woodworking

- Pros: Uniform thickness, saves sanding time, perfect joints, professional results, consistent quality

- Cons: More expensive, still requires edge finishing, limited thickness options, premium pricing

16. Laminated Plywood

Laminated plywood features a synthetic layer bonded to the surface, creating scratch-resistant finishes in countless colors and patterns.

This protective coating mimics wood, stone, or solid colors while standing up to daily wear better than natural veneers.

- Made From: Plywood core with high-pressure laminate (HPL) or low-pressure laminate (LPL) surface

- Grades Available: Decorative grade, cabinet grade, commercial grade

- Common Uses: Kitchen cabinets, bathroom vanities, office furniture, retail displays, countertops

- Pros: Scratch resistant, easy to clean, moisture-resistant, wide color range, affordable

- Cons: Can chip at edges, shows wear at corners, difficult to repair, synthetic appearance

17. Veneer Plywood (Decorative Hardwood)

Veneer plywood showcases real hardwood faces that highlight natural grain patterns and rich colors. Different types of plywood in this category let you choose from exotic woods like teak or classic options like oak.

- Made From: Plywood core with premium hardwood face veneers (oak, walnut, cherry, maple, teak)

- Grades Available: A-grade (premium), B-grade (good), rotary-cut, quarter-sawn

- Common Uses: Fine furniture, built-in cabinets, wall paneling, doors, types of window casings

- Pros: Beautiful natural grain, takes stain well, authentic wood look, can be refinished

- Cons: More expensive, requires sealing, susceptible to scratches, surface veneer can peel if damaged

18. Pre-Finished Plywood

Pre-finished plywood arrives ready to install with factory-applied stains, paints, or clear coats already cured. Builders appreciate how it speeds up jobs while giving DIYers professional results without spray equipment or finishing expertise.

- Made From: Hardwood or softwood plywood with factory-applied UV-cured finishes, lacquers, or polyurethanes

- Grades Available: Paint-grade, stain-grade, clear-coat grade (matte, satin, gloss finishes)

- Common Uses: Cabinets, shelving, wall panels, ceiling treatments, built-in furniture

- Pros: Ready to install, consistent finish, saves time, no finishing odors, professional appearance

- Cons: Higher cost, limited color choices, difficult to repair scratches, can’t be restained

19. Texture Plywood

These specialty sheets come with grooves, channels, or decorative reliefs that create shadow lines and architectural interest.

You can use them to break up flat surfaces and add character to walls, ceilings, or furniture panels without additional trim work.

- Made From: Softwood or hardwood plywood with routed, embossed, or stamped surface patterns

- Grades Available: Board-and-batten style, V-groove, channel groove, custom patterns

- Common Uses: Accent walls, ceiling panels, cabinet doors, room dividers, wainscoting

- Pros: Adds visual depth, hides imperfections, unique appearance, modern aesthetic

- Cons: Collects dust in grooves, harder to clean, limited availability, and more expensive

20. UV Coated Plywood

UV-coated plywood features an ultraviolet-cured glossy or matte finish that’s extremely hard and durable.

This high-tech coating process creates a mirror-like surface or subtle sheen that resists scratches, stains, and chemicals better than traditional finishes.

- Made From: MDF or plywood core with multiple layers of UV-cured acrylic or polyester finish

- Grades Available: High gloss, semi-gloss, matte finish, super matte

- Common Uses: Modern cabinets, contemporary furniture, retail fixtures, type of windows shutters, display units

- Pros: Extremely durable, brilliant finish, stain resistant, scratch resistant, easy to clean, doesn’t yellow

- Cons: Very expensive, shows fingerprints (high gloss), requires careful handling, limited repair options

Decorative plywood options prove you don’t need solid wood to achieve stunning results. Choose based on your style preferences, maintenance requirements, and budget to get surfaces that look great and perform reliably for years.

Choose the Right Plywood Grade for Your Project

Plywood grades indicate quality and appearance across different types of plywood, ranging from smooth, defect-free surfaces to rough panels with knots and patches, helping you choose the right option for your project.

| Grade | Surface Quality | Best For | Cost |

|---|---|---|---|

| A | Smooth, paintable, no knots | Cabinets, furniture faces, visible surfaces | Highest |

| B | Smooth with minor patches, tight knots allowed | Cabinet sides, underlayment, paint-grade projects | High |

| C | Knotholes up to 1.5″, some splits, rough patches | Sheathing, structural work, hidden surfaces | Medium |

| D | Large knots, knotholes up to 2.5″, splits are common | Roof decking, subfloors, packaging, and concrete forms | Lowest |

Tips for Selecting the Best Plywood for Your Needs

Picking the wrong plywood wastes money and creates headaches. Match different types of plywood to your specific needs, not just the cheapest option.

Smart selection considers where you’ll use it, the conditions it’ll face, and the required performance. Here’s what to evaluate before buying.

- Consider Your Environment: Indoor projects need different plywood types than outdoor applications.

- Match Grade to Visibility: Save money by using A-grade only where people see it. Hidden structural areas work fine with C or D grades, while furniture faces and the type of window casings deserve premium surfaces.

- Budget vs. Performance: Balance cost against longevity. Cheaper options might need replacement sooner, while specialty plywood lasts longer but costs more upfront.

- Check Thickness Requirements: Structural applications need thicker sheets (3/4″ or more), while decorative panels work with thinner options. Building codes specify minimum thickness for floors, roofs, and walls.

- Verify Your Tools Can Handle It: Some plywood is harder to cut, or it may require special blades. Make sure your saw, drill bits, and fasteners match the material you’re buying.

Think through these factors before heading to the lumber yard, and you’ll get the right different types of plywood for professional results that last.

Conclusion

Different types of plywood serve specific purposes; marine plywood handles moisture, while others are suited for cabinets or basements, making the right choice essential.

Hardwood plywood looks great; structural plywood adds strength. Match the type to your needs and budget.

Before your next hardware store visit, I recommend considering where the plywood will go and the conditions it’ll face. Taking those extra minutes to choose correctly saves you from costly do-overs later.